When it comes to filtering liquids in labs or other precise settings, syringe filters are absolute game-changers. They’re simple, efficient, and save so much time compared to traditional filtration methods. Whether you’re working with solutions in research, pharmaceuticals, or even DIY projects, knowing how to use a syringe filter properly is essential for clean, reliable results.

What Is A Syringe Filter?

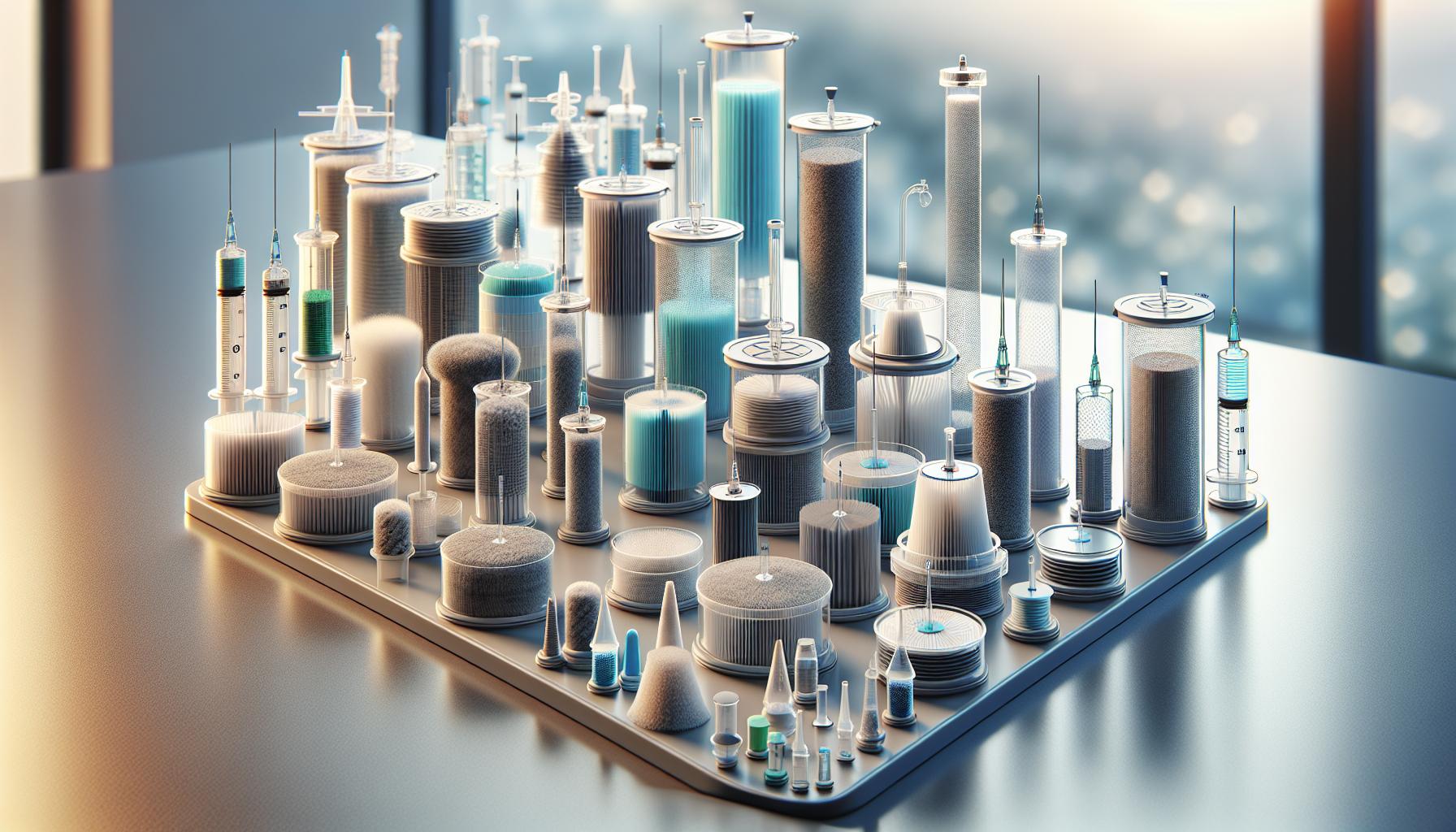

A syringe filter is a single-use device designed to remove particles or contaminants from liquids. It has a plastic body with a membrane that acts as the filtration medium. These filters are typically attached to the tip of a syringe to streamline liquid filtration.

Syringe filters come in a variety of membrane materials, including nylon, PTFE, and PVDF. Each material is suited for specific applications, such as chemical resistance or compatibility with aqueous solutions. For example, PTFE membranes are ideal for filtering aggressive solvents, while nylon membranes work well for aqueous and organic samples.

Filters are available in different pore sizes, ranging from 0.1 to 0.45 microns. Smaller pores, such as 0.22 microns, are commonly used for sterilizing solutions, while larger options are suited for basic particle removal. The choice of pore size depends on the application requirements.

This device is widely used in laboratories, research, and pharmaceutical processes. It ensures precision and cleanliness in sample preparation, analysis, and production workflows. By providing consistent and high-quality filtration, syringe filters maintain the integrity of results across various uses.

Types Of Syringe Filters

Syringe filters come in various types, offering versatility for specific laboratory applications. Material and pore size are key factors that define their functionality.

Material Types

Material types cater to filtration needs by providing compatibility with various liquids. Common membrane materials include:

- Nylon: Resistant to alkaline solutions, ideal for aqueous and organic samples.

- PTFE: Handles harsh chemicals, solvents, and high temperatures for chemical filtration.

- PVDF: Suitable for proteins and biomolecules with low protein binding properties.

- PES: Best for cell cultures and biological samples due to high flow rates and low protein adsorption.

- Regenerated Cellulose: Effective for both aqueous and organic solvents, ensuring minimal extractables.

Pore Sizes

Pore sizes determine particle retention levels critical for achieving desired filtration results. Popular sizes include:

- 0.1 Micron: Suited for sterilization and removing fine microorganisms.

- 0.2 Micron: Common for sterilizing aqueous solutions.

- 0.45 Micron: Ideal for general filtration of larger particulates.

- 1-5 Micron: Used for pre-filtration and removal of coarse particles.

These features allow syringe filters to match specific application requirements accurately.

When To Use A Syringe Filter

I use a syringe filter whenever a liquid sample requires filtration to remove particles, contaminants, or microorganisms. These filters are essential in laboratories and industrial processes where purity and precision are crucial.

- Sample Preparation

I rely on syringe filters to prepare samples for chromatography, spectroscopy, or other analytical methods. Filtration ensures no particulate matter interferes with instrument performance.

- Sterilization of Solutions

For sterilizing small-volume solutions, I opt for syringe filters with a pore size of 0.22 microns. These membranes effectively remove bacteria and microorganisms.

- Protein or Biochemical Analysis

I use filters, like PVDF membranes, to protect sensitive analyses. Filters minimize protein binding, preserving sample integrity.

- Removal of Precipitates

To remove crystals, precipitates, or undissolved matter, I utilize filters with pore sizes ranging from 0.45 to 5 microns, ensuring smooth processing.

- Aqueous and Organic Solvents

I choose filters based on solvent compatibility: nylon for aqueous solutions, PTFE for strong acids or organics, and regenerated cellulose for mixed solvents.

- Cell Culture Applications

For media or buffer solutions in cellular environments, I prefer PES filters to maintain sterility while minimizing contamination risks.

Using syringe filters supports consistent, reliable outcomes across applications where clean, contaminant-free liquids are necessary.

Step-By-Step Guide On How To Use A Syringe Filter

Properly using a syringe filter ensures accurate and contamination-free results. Follow this guide to perform the process efficiently.

Preparing Your Sample

Prepare the liquid sample to ensure it matches the intended filtration parameters. Avoid overloading by keeping the volume below the syringe’s maximum capacity. If the sample contains particles larger than the filter’s pore size, pre-filtration may be necessary to prevent clogging.

Selecting The Right Syringe Filter

Choose a filter based on the sample’s properties and application. Select a compatible membrane material, such as PTFE for organic solvents or PVDF for protein solutions. Match the pore size to the filtration goal, like 0.22 microns for sterilization or 0.45 microns for particle removal. Confirm the filter diameter suits the syringe volume.

Assembling The Syringe And Filter

Attach the syringe filter to the syringe’s nozzle firmly but gently. Hold the syringe upright to avoid air entering the filter. Push and twist the luer lock connection for a secure fit, ensuring there are no leaks.

Filtering The Sample

Pull the plunger to draw the sample into the syringe. Hold the assembly vertically and push the plunger steadily to pass the liquid through the filter. Avoid excessive force to prevent damaging the membrane. Stop filtering if resistance increases significantly.

Disposing Of The Filter

Discard the used syringe filter immediately after filtration. Dispose of it in accordance with laboratory or local biohazard regulations. Avoid reusing single-use filters to prevent contamination.

Tips For Effective Syringe Filter Usage

- Choose Compatible Materials

Select a syringe filter with a membrane material that matches your sample’s chemical composition. For instance, use PTFE for organic solvents or harsh chemicals, nylon for aqueous and alkaline solutions, and PVDF for proteins or sensitive analyses.

- Select Proper Pore Sizes

Match the pore size to the intended application. Use 0.22-micron filters for sterilization, 0.45-micron filters for general filtration, or larger pore sizes like 1 micron for pre-filtration processes.

- Avoid Overloading the Filter

Maintain the liquid volume within the manufacturer’s specified limit. Exceeding this capacity could lead to membrane rupture or inefficient filtration.

- Apply Consistent Pressure

Press the syringe plunger steadily without exerting excessive force. Uneven pressure might damage the membrane or result in incomplete filtration.

- Pre-Filter Cloudy Samples

If the sample contains visible particulates, use a larger pore size pre-filter before the final filtration. This prolongs the life of finer membranes and improves efficiency.

- Minimize Air Bubbles

Remove air from the syringe before attaching the filter. Air bubbles may disrupt flow and reduce filtration accuracy.

- Maintain Sterility

Handle sterile filters in a clean environment to prevent contamination. Use gloves and avoid direct contact with the membrane.

- Dispose of Filters Properly

Dispose of used syringe filters following your lab’s waste protocols. Some filters require specific disposal methods based on sample contaminants or chemical residues.

Using correct techniques and components enhances filtration performance while protecting both the sample and results.

Common Mistakes To Avoid

- Using incompatible membranes

Choosing the wrong membrane material leads to sample contamination or membrane damage. For instance, avoid using nylon with acidic solutions or PVDF with strong bases.

- Ignoring pore size suitability

Using incorrect pore sizes results in incomplete filtration or inefficiency. Do not use a 0.45-micron filter for sterilization when a 0.22-micron filter is required.

- Skipping pre-filtration

Directly filtering turbid samples clogs membranes. Pre-filter cloudy liquids to extend the syringe filter’s lifespan and effectiveness.

- Applying excessive force

Applying too much pressure when filtering damages the membrane or causes leakage. Maintain consistent, moderate force during filtration.

- Reusing single-use filters

Reusing syringe filters compromises sterility and accuracy. Always use a new filter for every sample to prevent cross-contamination.

- Overloading the filter

Filtering large volumes exceeds the filter’s capacity. Divide the sample into smaller portions if necessary to avoid clogging.

- Improperly assembling components

Incorrectly attaching the syringe and filter results in leaks or inefficient filtration. Ensure a secure connection before starting the process.

- Neglecting air removal

Air bubbles interfere with consistent filtration flow. Prime the filter by passing a small amount of liquid through it before starting the filtration.

- Failing to dispose of filters safely

Improper disposal leads to contamination or regulatory non-compliance. Discard used filters following laboratory safety protocols.

Conclusion

Using syringe filters effectively is a straightforward yet crucial step in achieving reliable and contamination-free results in laboratory workflows. By selecting the right filter, following proper techniques, and avoiding common mistakes, you can ensure optimal performance and protect the integrity of your samples.

Whether you’re working in research, pharmaceuticals, or industrial applications, syringe filters play an essential role in maintaining precision and cleanliness. With the right approach, these tools can simplify your processes while delivering consistent and high-quality outcomes.

Frequently Asked Questions

What is a syringe filter?

A syringe filter is a single-use device designed to remove particles, contaminants, or microorganisms from liquid samples. It consists of a plastic shell housing a filtration membrane, available in various materials and pore sizes, to ensure clean and reliable sample preparation.

Why are syringe filters important in laboratories?

Syringe filters are crucial for ensuring precision and cleanliness in laboratory processes. They effectively remove impurities, protect sensitive analyses, and help maintain sample integrity in applications like chromatography, protein studies, and sterilization.

What are the common membrane materials used in syringe filters?

Common membrane materials include nylon, PTFE, PVDF, PES, and regenerated cellulose. Each material has specific compatibility with different liquids, such as harsh chemicals, proteins, or cell culture solutions.

What pore sizes are available in syringe filters, and what are their uses?

Pore sizes range from 0.1 to 5 microns. For sterilization, 0.22-micron filters are used, while larger pores, like 5 microns, are suitable for pre-filtration or removing precipitates.

How do I choose the right syringe filter?

Choose a syringe filter based on your sample’s chemical composition, required sterility level, and particle retention needs. Consider membrane compatibility and pore size to match your application.

Can syringe filters be reused?

No, syringe filters are designed for single-use only. Reusing them can result in contamination, membrane clogging, and compromised sample accuracy.

What are the steps to use a syringe filter effectively?

Prepare your liquid sample and select an appropriate filter. Assemble the syringe and filter, apply consistent pressure during filtration, and safely dispose of the used filter according to lab protocols.

What are common mistakes to avoid when using syringe filters?

Avoid using incompatible membranes, ignoring pore size suitability, applying excessive force, overloading filters, skipping pre-filtration for cloudy samples, and improperly disposing of used filters.

Why is pore size important in syringe filters?

Pore size determines the filter’s ability to retain particles or microorganisms. Smaller sizes like 0.22 microns ensure sterilization, while larger sizes handle pre-filtration or remove visible impurities.

How can I improve filtration efficiency with a syringe filter?

Use compatible membrane materials, avoid overloading the filter, pre-filter cloudy samples, apply consistent pressure, and minimize air bubbles to maintain smooth flow and precise results.

Are syringe filters suitable for protein studies?

Yes, syringe filters with PVDF membranes are ideal for protein studies as they ensure high recovery rates and maintain sample integrity by preventing contamination or loss.

How should syringe filters be disposed of?

Dispose of used syringe filters according to your institution’s laboratory waste disposal regulations. Proper disposal is essential to maintain safety and meet environmental guidelines.

What role does sterility play in syringe filtration?

Sterility ensures the absence of microorganisms in filtered samples, crucial for applications like cell culture or solution sterilization. Use 0.22-micron sterile filters for small volumes to achieve this.

What filters are recommended for harsh chemical filtration?

PTFE syringe filters are highly resistant to harsh chemicals and solvents, making them suitable for aggressive solutions or organic solvents in laboratory processes.